1. Background information

Due to the rapid development of new materials and new energy industries, there is a strong demand for high-end lithium products, especially battery grade and high-purity lithium carbonate. Lithium carbonate production process can be divided into two categories due to different resources: lithium extraction from ore and lithium extraction from salt lake brine. The main raw material of lithium carbonate produced by foreign companies is salt lake brine. In recent years, although China is also actively developing lithium resources in salt lakes, the development progress is slow due to resource conditions, technology and other factors. The main raw material for the production of lithium carbonate in China is still solid ore.

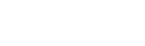

At present, most battery grade lithium carbonate production in China adopts spodumene sulfuric acid method. Its process includes high-temperature transformation of spodumene concentrate, grinding, acidification, leaching lithium sulfate solution, impurity removal and purification into purification solution, evaporation and concentration into lithium sulfate concentrated purification solution, lithium precipitation, filtration and separation, lithium carbonate washing, drying, airflow crushing, packaging and other processes.

Technological process of sulfuric acid method for extracting lithium from ore

2. New process of StarOne

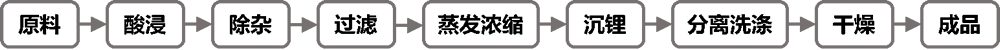

Based on the needs of national industrial policies and the clean production needs of the lithium industry, and in line with the mission of taking source innovation as the main driving force and promoting industrial technology upgrading, StarOne has studied the new technology of lithium salt production by sulfuric acid method, focusing on changing the problems of large energy consumption, high treatment cost and serious pollution of traditional evaporation concentration method.

New process flow of StarOne

3. Process advantages of StarOne

1. It can replace the evaporator or reduce the evaporation capacity.

2. The energy-saving benefit is obvious, and the evaporation cost is saved by 30%.

3. The cost is greatly reduced and the investment payback period is short.

4. High product quality and less total pollutant emission.

5. High quality pure water can be recycled.

StarOne's new process can bring great technological upgrading to the development of relevant industries, improve product quality, save energy and resources, realize circular economy, and promote the technological progress and rapid development of national energy conservation and environmental protection industry. Take the lithium industry as an example: the existing capacity of lithium carbonate in China is 400000 tons / year. If all this technology is adopted, the annual benefits for lithium production enterprises will be 320-400 million yuan. Reduce energy consumption and convert it into standard coal of about 450000 tons / year; Save water consumption of about 3.2 million tons / year; At the same time, sulfur dioxide emission can be reduced by 6000 ~ 12000 tons / year; Reduce dust emission by about 3000 ~ 6000 tons / year; Reduce NOx emission by about 4000 ~ 6000 tons / year; Reduce carbon dioxide emissions by 360000 ~ 420000 tons / year.

4. Industry cases

Take the lithium sulfate concentration project of a lithium industry company as an example:

At present, the lithium sulfate solution of the enterprise adopts the process of evaporation and concentration. According to the on-site communication and investigation, the current process has the disadvantages of high operation cost, large total pollutant emission and many auxiliary equipment. In order to reduce the production cost, completely solve the environmental protection problems and improve the competitiveness of the enterprise, the existing evaporation can be replaced by StarOne membrane concentration process, which can effectively solve the above problems.

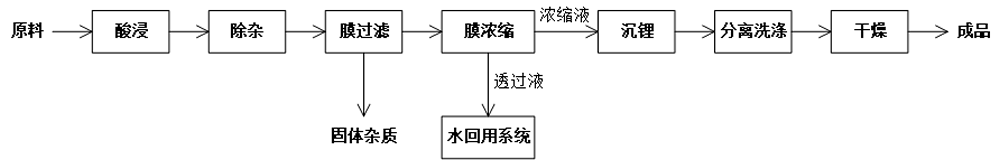

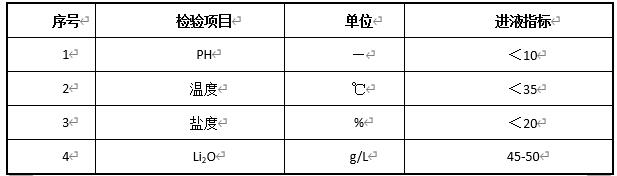

Lithium sulfate inlet water quality:

According to the requirements of the owner, the effluent requirements of the membrane system after concentration are as follows:

For more details, please call 028-61747878